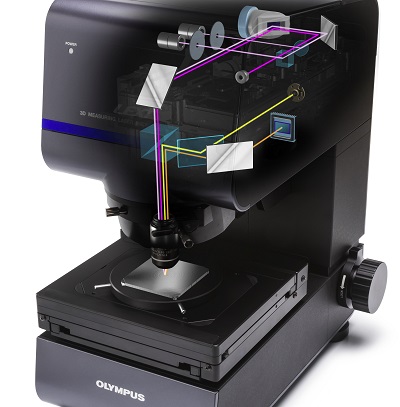

OLS5000

The OLS5000 laser confocal microscope precisely measures shape and surface roughness at the submicron level. Data acquisition that’s four times faster than our previous model delivers a significant boost to productivity.

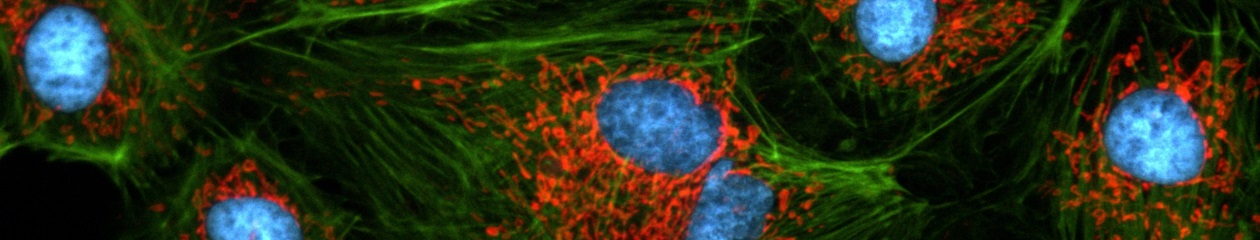

High-resolution, precise imaging

With the capability to make accurate 3D measurements on a wide range of sample types, the system delivers reliable data for quality assurance and process control.

Excellent lateral resolution

The 405 nm violet laser and dedicated high-NA objectives make it possible to capture fine patterns and defects that conventional optical microscopes, white-light interferometers, or red laser-based microscopes are unable to detect.

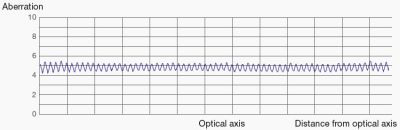

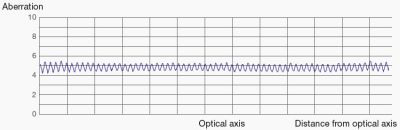

Uniform measurement values

Dedicated LEXT objectives can accurately measure peripheral areas that would otherwise get distorted.

LEXT objectives

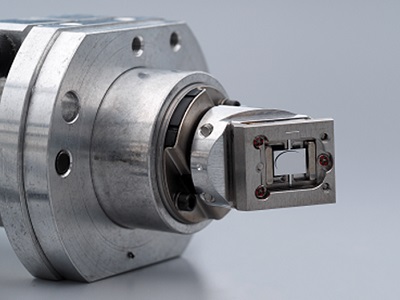

Newly developed MEMS Scanner

New MEMS scanner performs accurate X-Y scanning with low scan trace distortion and minimal optical aberrations.

4K scan technology

The 4K scan technology scans 4,096 pixels — four times more than our previous model — in the X-axis direction.

The OLS5000 microscope can detect slopes that are almost vertical as well as very low steps without image correction.

Capturing the true shape

Because conventional laser microscopes use standard image processing techniques such as smoothing to eliminate noise, they sometimes lose accurately measured fine height irregularities along with the noise.

The OLS5000 microscope employs Olympus’ Smart Judge algorithm to automatically detect only reliable data, facilitating accurate measurements without losing fine height irregularity data.

Other high-resolution measurement technologies

- PEAK algorithm

- Dual confocal system

- Sq noise (measuring noise) guarantee

- Accuracy and repeatability are guaranteed

- Hybrid matching algorithm

- Hybrid dampening mechanism

- HDR scan